Design Tips for Injection Moulding

This article sums up the best practices for designing injection moulding to help you get quality polymer parts at a reasonable cost.

The injection moulding process is widely used in large volume production as it produces comparatively low scrap production and has high repeatability. The versatility of the injection moulding process demands much broader design considerations. Most of the design considerations will be made on the mould after setting out the product requirements.

Some of the factors that affect the injection moulding design include: how the part will be used (singular product or for assembly), its dimensional and mechanical requirements, and its ability to withstand elements such as chemicals or pressure. Some vital tips to consider when designing for injection moulding are explored below.

1. Carefully choose materials suitable for your design

Different injection mouding materials offer varying properties. For example, some injection moulding materials provide more dimensional stability than others. Similarly, some bond better with adhesives than others. Material design considers the following: temperature, pressure, biological and chemical interactions.

Thermoplastic resins can be broadly classified into amorphous and semi-crystalline. While semi-crystalline thermoplastics offer better chemical and electrical resistance, their amorphous counterparts are much more dimensionally stable and more resistant to impact. Material selection can affect the required tolerance level or certain features, like wall thickness.

| Semi-crystalline resins | Amorphous resins | |

| Advantages | • Excellent for bearing, wear and structural applications • Good chemical and electrical resistance • Lower coefficient of friction | • Bond well with adhesives • High dimensional stability • Good impact resistance |

| Disadvantages | • Difficult to bond with adhesives • Average impact resistance | • Low resistance to fatigue and stress cracking |

2. Take into account the part tolerance

Tolerances are affected by the shrinkage that occurs during the cooling process. Amorphous materials like PLA generally have tighter tolerances than semi-crystaline materials like PEEK.

Tight tolerances make production more expensive, but they may be necessary for your part to fit or function properly, especially if it is used in an assembly.

We recommend contacting your supplier at the design stage to discuss the tolerance standards that they use.

For example, DIN16901 contains a general tolerance table as a reference for different materials. If your supplier uses this standard and you need tighter tolerances or other standards, they will ask you to provide 2D drawings.

3. Choose the right wall thickness

There are a few key points to consider to ensure you choose the right wall thickness for your injection moulding design:

- Thinner walls shorten the cycle time and lower the cost of your part. For lots of applications a wall thickness of 1.5-2.5 mm is sufficient, but you can also refer to recommended wall thicknesses for different materials

- Unlike CNC machined parts, plastic injection moulded parts benefit from a consistent wall thickness. If a part is thicker in one section than another, a sink mark will appear at that location.

- Non-uniform wall thicknesses also lead to warping, as these walls cool and shrink at different rates. If you require a non-uniform thickness, the change in thickness should not exceed 15% of the nominal wall thickness and should always have a smooth or tapered transition to achieve a high quality part.

The following are the recommended wall thicknesses for different materials:

| Material | Recommended wall thickness |

| ABS | 1.143 mm – 3.556 mm |

| Acetal | 0.762 mm – 3.048 mm |

| Acrylic (PMMA) | 0.635 mm – 12.7 mm |

| Liquid Crystal Polymer | 0.762 mm – 3.048 mm |

| Long-Fiber Reinforced Plastics | 1.905 mm – 27.94 mm |

| Nylon | 0.762 mm – 2.921 mm |

| PC (Polycarbonate) | 1.016 mm – 3.81 mm |

| Polyester | 0.635 mm – 3.175 mm |

| Polyethylene (PE) | 0.762 mm – 5.08 mm |

| Polyphenylene Sulfide (PSU) | 0.508 mm – 4.572 mm |

| Polypropylene (PP) | 0.889 mm – 3.81 mm |

| Polystyrene (PS) | 0.889 mm – 3.81 mm |

| Polyurethane | 2.032 mm – 19.05 mm |

4. Add draft angles to your design

Many material removal processes such as CNC machining can produce vertical walls. However, creating a part’s design for injection moulding with vertical walls will cause the part to get stuck, particularly at the core, as the part contracts on cooling.

If too much force is applied to eject the part, the risk of damaging the ejector pins and even the mould becomes very high. Design the walls of parts with a slight slant to avoid this problem. This slanting is called a draft.

Due to the high complexity, it creates in designing, the draft is usually added at the final stages of the part design. Different surfaces require varying drafts. Textured surfaces require the most draft. Some common surfaces found in injection moulding and their minimum draft angles are as follows.

- For “near-vertical” requirements: 0.5°

- Most common situations: 1 ~ 2°

- All shutoff surfaces: 3°

- Faces with light textures: 1 ~ 3°

- Faces with medium textures: 5°+

5. Add ribs and gussets to certain parts

Certain parts require ribs. Ribs and gussets give additional strength to parts and help to eliminate cosmetic defects like warping, sink and voids. These features are essential for structural components. Therefore, it is preferable to add them to parts rather than increase the thickness of parts to increase strength.

However, if not properly designed, this can lead to shrinkage. Shrinkage happens when the cooling rate of certain parts is much faster than others, resulting in the permanent bending of some sections. The warping can be effectively reduced by keeping the rib thickness between 50 – 60% of that of the wall it is attached to.

6. Add radii and fillet to part design

Applying radii to parts, when possible, eliminates sharp corners, which improves the flow of material and the part’s structural integrity. Sharp corners cause weakness in the part as the molten material is made to flow through the corner or into the corner. The only places where sharp corners are unavoidable are the parting surfaces or shut-off surfaces.

Radii and fillets also aid in a part ejection as rounded corners are less likely to get stuck during ejection than sharp corners. Furthermore, sharp corners are also not structurally advisable as they lead to stress points that can fail. Radii help to smoothen out the stress on the corners.

Also, including sharp corners in your part will exponentially increase the cost of production as this would require the mould to feature sharp corners that can only be achieved using very expensive manufacturing techniques.

Add internal radii at least 0.5 times the thickness of the adjacent wall and external radii 1.5 times the size.

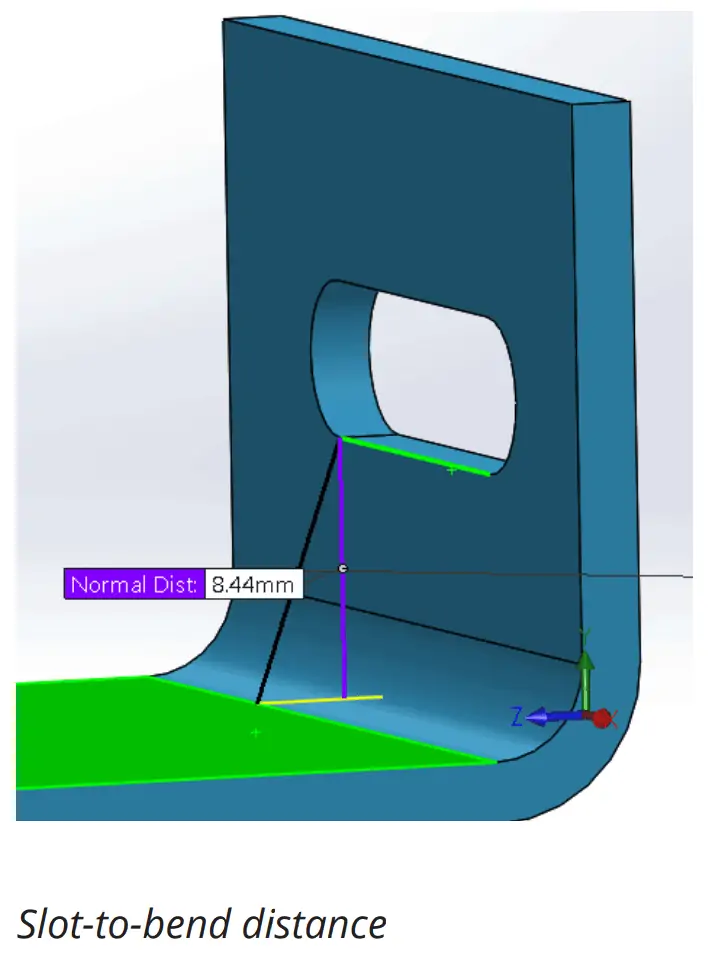

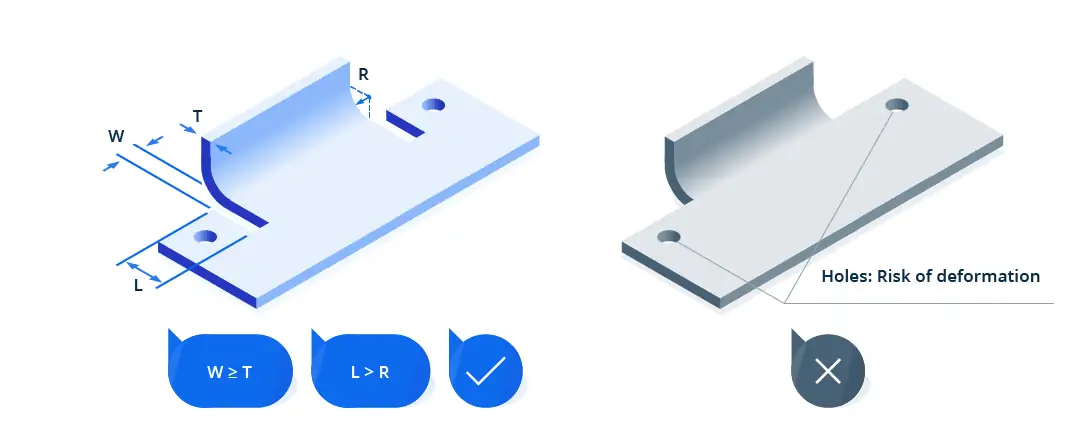

7. Avoid undercuts and provide slots where possible

Snap fits are obtainable through undercuts. The straight-pull mould, which consists of two halves, and is the most straightforward design, is not suitable to manufacture parts with undercut features. This is due to the difficulty in machining such a mould with CNC and the tendency of the material to get stuck on ejection.

Undercuts are usually created using side cores. However, side cores significantly increase tooling costs. Luckily there are some design tips to achieve the function of an undercut without using side cores. One way of doing this is by introducing a slot instead.

This is also referred to as a pass-through core. Another way is to adjust or move the parting line of the part. When doing this, also adjust the draft angle accordingly. Moving the parting lines is most suitable for undercuts that are on the outside of the part.

You can also use stripping undercuts, also referred to as bump offs. However, only use this feature when the part is flexible enough to deform and expand during ejection from the mould.

Also, give enough clearance: bump-offs must have a lead angle of 30° to 45° for effective ejection. All these alternatives to expensive side cores require significant redesigning of the part. When the redesign of a part is not possible due to the possibility that it may affect the functionality of the part, then you have to employ sliding side-actions and cores to deal with undercuts.

These features slide in as the mould closes and slide out as it opens. The side cores must move perpendicularly and have appropriate draft angles.

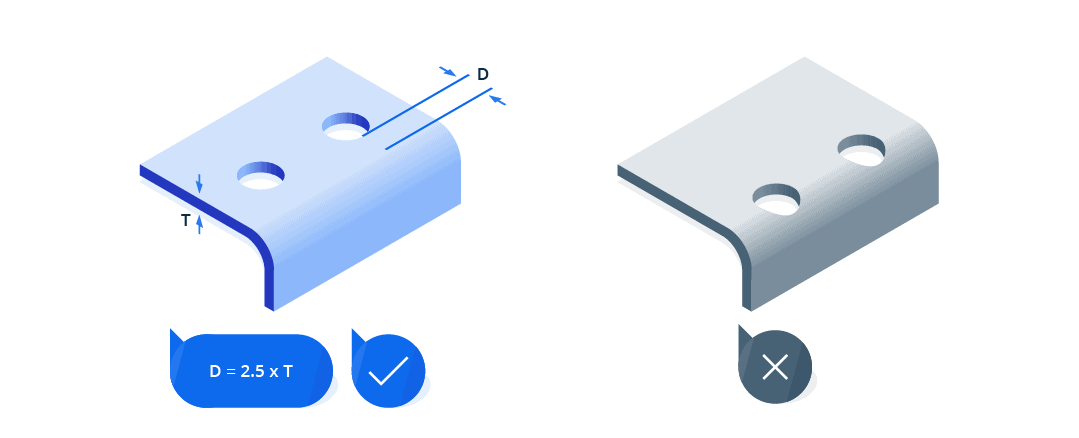

8. Attach bosses to side walls or ribs

Bosses are cylindrical standoffs moulded into a plastic part to accept an insert, self-tapping screw, or pin for assembling or mounting parts.

The outer diameter (OD) of the boss should be 2.5 times the diameter of the screw diameter for self-tapping applications.

Bosses shouldn’t be freestanding. Always attach bosses to a side wall or to the floor with ribs or gussets. Their thickness should not exceed 60% of the overall part thickness to minimize visible sink marks on the outside of the part.

For example, a part with an outer wall of 3 mm should have internal ribs that are no more than 1.7 mm thick.

9. Gating: Highlight visually important surfaces on your part where there must not be any marks

In order to properly design and manufacture your part using injection moulding, it is important for the manufacturer to understand from the outset what your requirements are in terms of its appearance.

One key point for the tool maker to consider is the gate location. Gates are entry sections through which the molten material enters the mould. The tool maker has to choose the type of the gates and position them strategically to minimize potential quality issues.

Gates also leave gate vestige or a visual indication that the part was gated—even if it is subtle.

That’s why we recommend letting your supplier know about any aesthetic and functional requirements and defining where not to gate.

Design your parts for injection moulding and source them with Eco Rapid

At Eco Rapid, we offer injection moulding services with over 30 materials, such as plastics, synthetic and silicone rubber, and elastomers. Simply contact us and get a free quote.